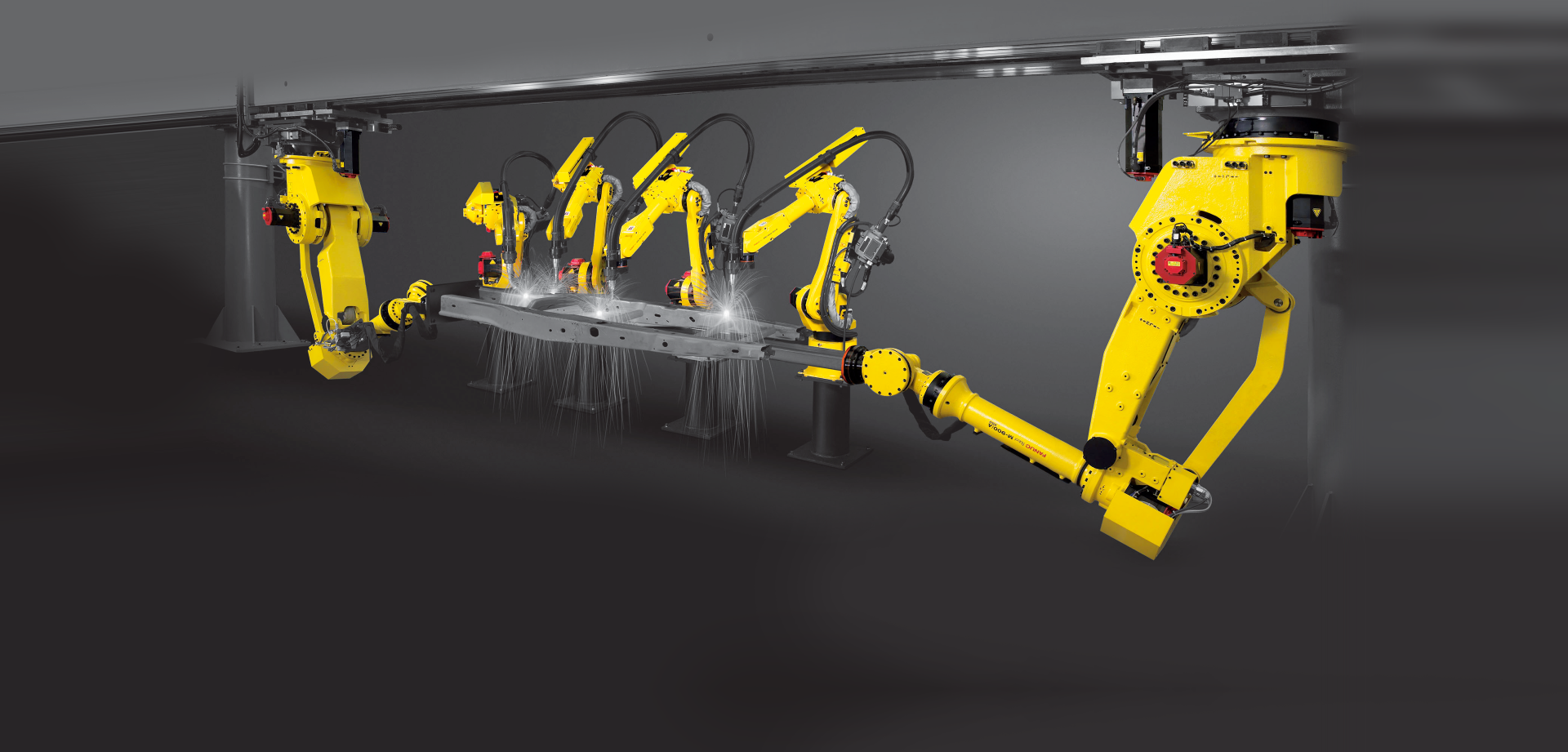

It was the goal of the project to create a robotic workplace with a FANUC device, as a separate welding unit

The implementation of modern industrial robots into welding applications brings production process automation and reduces production costs..

- compact robotic solution

- rotary table variability - customer chooses number of positions

- simple control

- quick rebuild or transport around the shop floor

- facilitating human work

- maximizing manufacturing efficiency

At the bottom of the machine there are channels for air and electricity distribution and holes for transport and handling by forklift. After installation, only electrical, air and shielding gas connections have to be made.

In the robotic welding unit there is a table which can be rotated manually with a diameter of 2000 mm with pneumatic locking of the welding position, for 2 separate workplaces (for fastening of welding jigs). These workplaces are separated by a screen and have air and power inlets for the positioner. The cell's interior is illuminated. The rotary table is connected to the frame and the base on which the welding robot is placed.

A cleaning and milling station for the welding torch is located inside the robotic system welding unit. The work area is equipped with a funnel including a fan for fume exhaust. These are led through a pipeline into a filtering unit hung on the back wall of the casing. At the back of the unit, behind the casing on the base, the welding robot control unit is located, the welding power supply, as well as the electrical distribution box, the drum with the wire and, optionally, the shielding gas container are located.

The entire automated welding unit can be easily moved by a forklift in case of a project change. The welding robot controls are connected by a cable with manual controls, or the so-called "teach pendant", which the operator used to manage, control, program and adjust the entire technological production process.