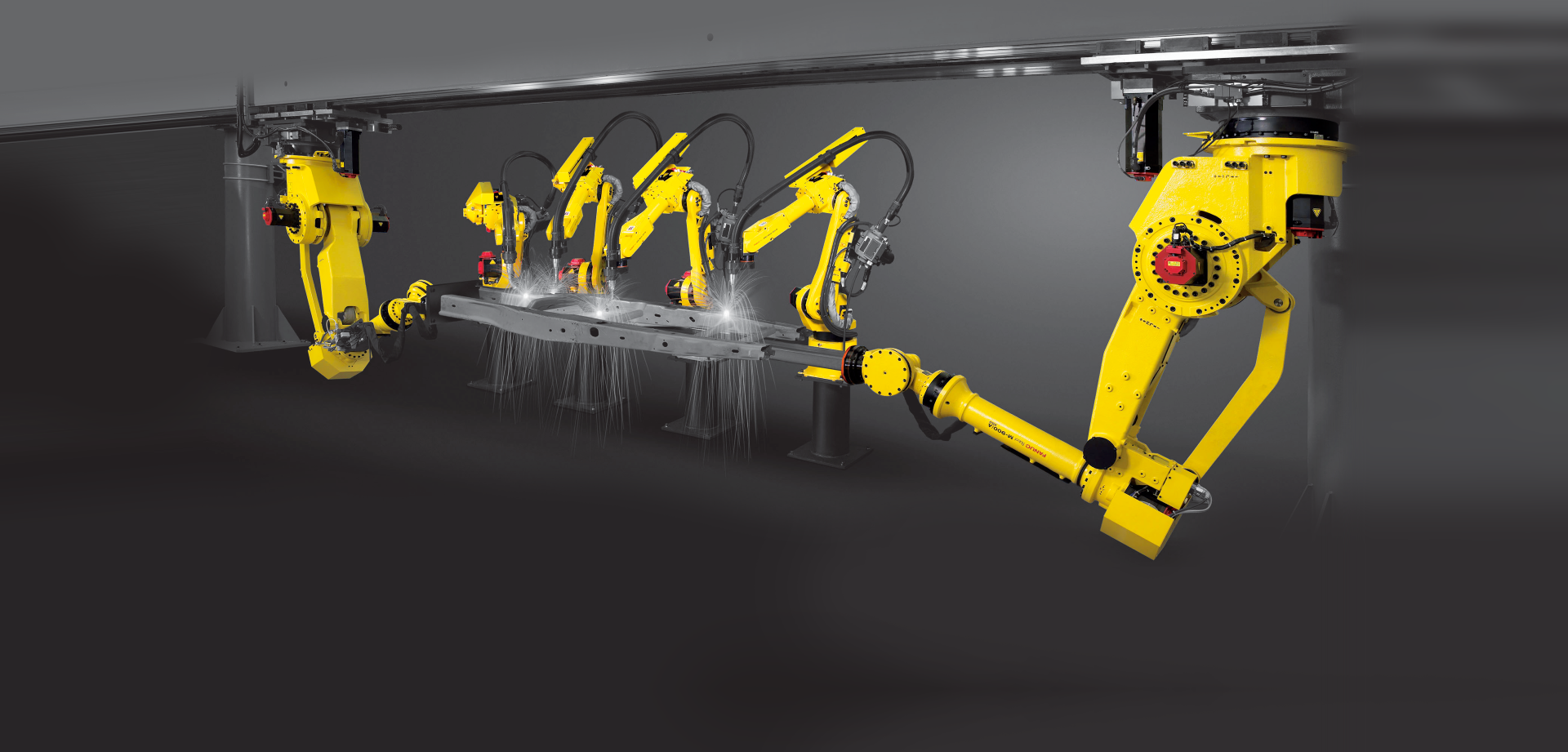

Automation for presses and injection moulding machines

Robot work cycle

The actual manufacturing process cycle consists of setting/removal of the moulded product from/into the press mould and positioning it on the output belt conveyor. The robot type and its location are determined by the size of the press or injection moulding machine.

Grippers

- flange according to the customer's request

- possibility of manual/automatic exchange system

- vacuum grippers

- gripper control using valves/ejectors located on the robot’s third axis

Part input

- none - removing mouldings directly from the press

- removing excess metal bits from the pallet

- belt conveyor with camera

- removing the preforms from the conveyor, placing them in a press where the final plastic part is injected

Part output

- conveyor belt

- assembly jig

- clipping station