A workplace that will help replace the operator’s monotonous and strenuous work

More specifically, the goal of the project was to create a workplace that would make it easier to put metal clips onto plastic spikes.

- a robotic solution for precise clip mounting on a plastic spike

- minimal scrap and potential scrap selection

- sensor-controlled deployment and full pressing of the clip into the correct position

- possibility of clipping more types of plastic parts

- facilitating human work

- maximizing manufacturing efficiency

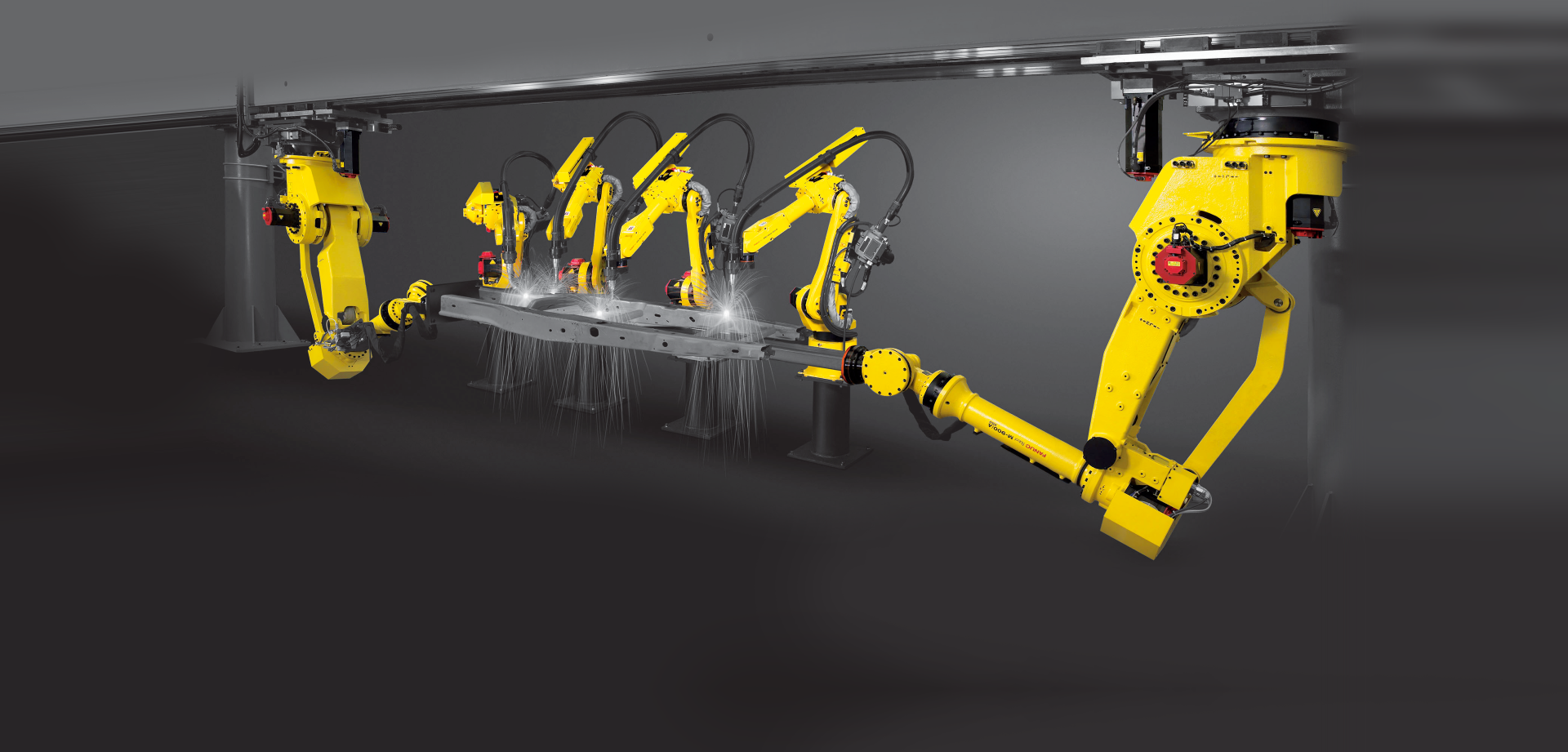

An independent robotic unit with a FANUC M-10iA/10M robot, fitted with SCHUNK grippers with tongs, tailored for precise clip gripping, is the solution. The robot gripper is also equipped with an induction sensor to control the exact position of the clip after its deployment. The workplace also includes 2 loading windows, protected by security barriers.

Each of the windows has a frame for securing the clamping jig. The plastic parts are inserted directly into the clamping jigs by the operator. When the robot is clipping in one loading window, it is possible for the operator to place parts into the other window.

The workplace will be located on an anchoring base and will be able to be moved by using transport technology. A vibrating storage with a vibrating tray is used to feed the metal clips to the robot.