It was the aim of the project to develop a modern technological solution for a precise small product assembly process

Here, in a prototype and single-purpose solution, it is specifically two new types of plastic button components, each button consisting of an outer sleeve, a metal spring and an internal spike.

We solved operational issues related to large-volume or larger continuous production for the customer. Or rather the finishing operation in the form of general assembly and verification of the resulting state of the assembled unit with regard to the small plastic parts.

- robotic solution for precise assembly and controlling of plastic buttons

- minimal scrap and potential scrap selection

- inspection by camera of the correct shape of the mouldings

- customizability for multiple button types

- facilitating human work

- maximizing manufacturing efficiency

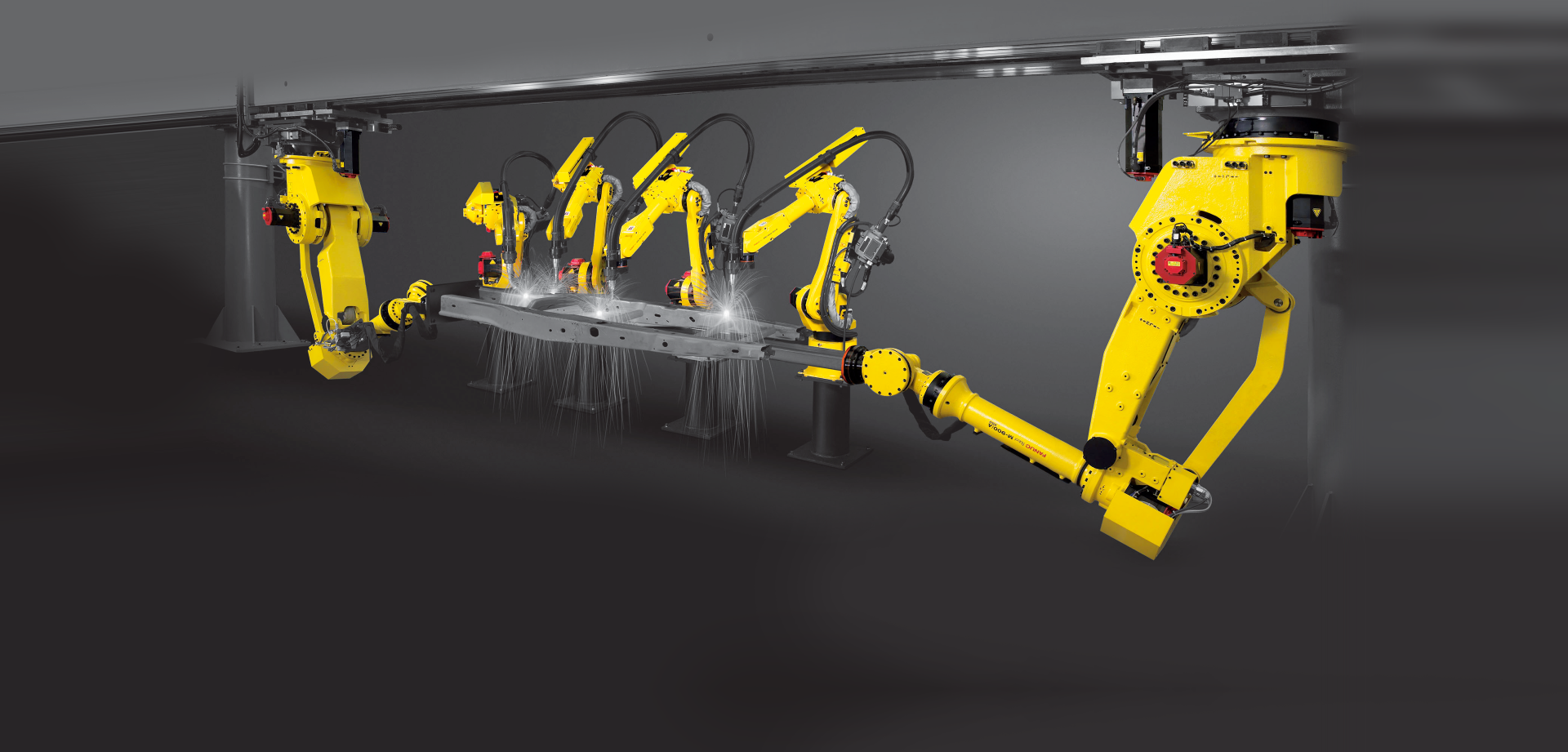

The solution is conceived as a separate robotic unit with a FANUC M-10iA/10M robot. It is fitted with two parallel grippers for handling plastic mouldings and parallel grippers for handling the springs.

As part of the comprehensive solution a workplace was set up which is furthermore equipped with 4 vibrating storage bins with vibrating trays for plastic parts feed, storage for loading the springs manually, 2 jigs for positioning the button parts, a control station with a camera for part quality control and an output conveyor. The workplace is secured by protective railing. The workplace operates at a pace of 25 pcs/s.